-

1st FRP boat Builder in Taiwan - SSF

Sophisticated and Advanced Yachts with Seasonal Experience

43 years of boat building experience with advanced technology

-

Fiberglass Boat Built With Advanced Technology - 100% One-Stop Fiberglass Boat Building

Indestructible fiberglass boat with luxury interior design

43 years of boat building experience with advanced technology

high quality, reasonable price, 100% One-Stop fiberglass boat builder -

SHING SHENG FA BOAT BUILDING CO., LTD.

In 1971 Shing Sheng Fa had already manufactured and delivered nine 100 feet fishing trawlers

In 1971 Shing Sheng Fa had already manufactured and delivered nine 100 feet fishing trawlers

In 1980, when the U.S. army came to Taiwan for vacation during the Vietnam war, they noticed Taiwanese fishermen's skillful techniques on building boats, so they started to purchase yachts for themselves, which allowed "Made In Taiwan" yachts to match fine features for worldwide yacht lovers.

Years later, the high security and performance requirements of yachts' increased, which encouraged Taiwanese boat builders to make efforts to upgrade their capabilities. Hence, FRP (Fiber Reinforced Plastic) yachts entered the market as a high technology replacement of wooden yachts.

Like people say nowadays, "if you want to buy a luxury yacht that is designed by a famous designer, you go to Italy; but if you are looking for a yacht that is built with high quality and acceptable price, you can find one in Taiwan." ![]()

SHING SHENG FA BOAT BUILDING CO., LTD. (SSF), among more than twenty boat builders, SSF was the first boat builder who started to build fiberglass boats in Qijing, Taiwan. For more than 43 years, SSF has been dedicated to designing sophisticated boats and developing their manufacturing technologies in order to stay competitive in the market. So far, SSF has 100% boat design and manufacture abilities to build boats in compliance with international standards.

Fiberglass boats, FRP boats, are totally strong! They are water resistant, do not rust or corrode, are low maintenances and durable. They perform the way wooden boats can't. With the best fiberglass and building techniques developed by SSF engineers, it is easier than ever to build boats.

Qijing is a town near Kaohsiung located in southwestern Taiwan. Besides sea food and beaches, it is also a district which has made Taiwan one of the world’s top 7 luxury yacht manufacturing countries. LVMH Chief Bernard Arnault, German racing driver Ralf Schumacher and the owner of Swarovski all purchased luxury yachts in Taiwan.

"Made in Taiwan" yachts have even been featured on American TV shows. Therefore, Taiwan boat builders' strong customization and innovation yacht design capabilities have attracted wealthy people worldwide. With their solid reputation and more than NT$50 billion (US$ 1.5 billion) in revenues, Taiwan’s boat builders have been encouraged to upgrade their technologies in order to build sophisticated and advanced yachts.

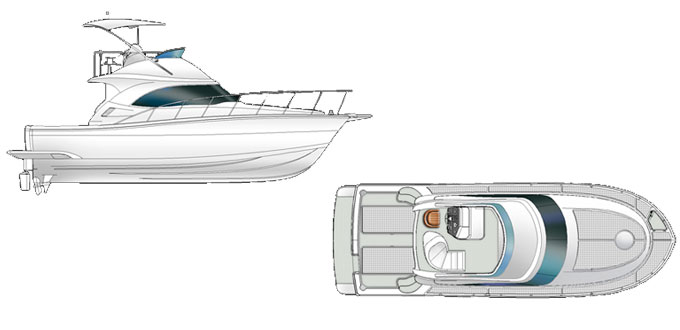

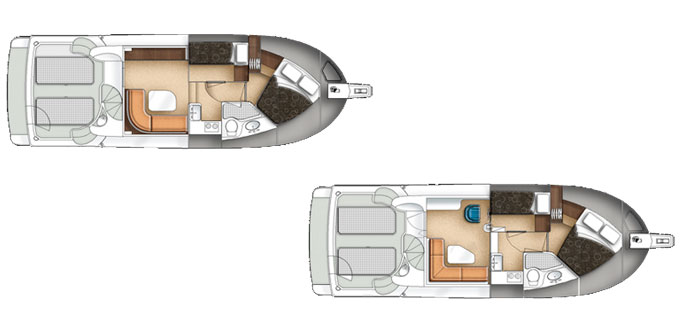

Boat Design

In SSF, the design team, with 43 years of boat design experience, designs every client's boat based on their requests. The 3D and 2D boat design contains exterior styling sketches and renders, interior layouts and general arrangements. When the specific designer is assigned, SSF works with architects to assure the overall design complements.

Boat Mould Design

When building moulds, it is critical to ensure every wood piece is cut precisely. In mould making, thin strips of wood are placed over a mould in layers. A computerized saw cuts wood pieces, and they are used for the moulds for the fiberglass boats.

Mold making is similar to construction of a fiberglass boat, except it involves the use of epoxy or polyester resins. It takes more than a year to design and construct a mould, and the mould must be perfect in order to make a cast of a boat. contact SSF for boat building

Material For Building A Yacht – Fiberglass

Fiberglass is the perfect material for building boats because it is corrosion resistant, maintenance free, stretch free and perfect for making lightweight, sleek, fast and strong boats.

SSF uses high quality fiberglass to assure the lamination process is done properly. There are various sizes and weights of fiberglass. Each fabric is made by fiberglass and wide knitted within certain patterns including biaxial, triaxial, and uni-directional knitted fiberglass. There are also woven and matt fiberglasses with different weights. see fiberglass boats

Boat Lamination

When laminating a boat, the boat is covered with fibreglasses at a 45 degree or 90 degree angle to enforce its strength and toughness. Dynel cloth is also utilized for adding abrasion resistance. Laminating epoxy is spread all over the entire boat as soon as the fiberglass cloth is evenly laid down.

The procedure is repeated until the desired thickness if achieved. The workers have to ensure the fiberglass is applied in every corner, because if it isn’t applied properly, the boats will have structural defects. contact SSF for your luxury boat

Boat Wiring and Plumbing

To assure maximum waterproofing, isophthalic gelcoat and layers of mats are applied. After lamination is done, the casting is removed from the mould, and the mechanics start to work on the holes of the boat, including windows, hatches, wood trims, lighting, opening ports, electrical circuits, etc. Then the mechanics put the hull and the deck together, and the electrical wiring and plumbing are installed.

Boat Home Furnishings

Interior design is yet another complementary service SSF offers to their buyers. SSF's design staff gets to know you and your taste so they can make suggestions to you about home furnishings, flooring, window coverings and accessories. In addition, certain components are installed by hand such as the dashboard, hand grips, etc.

Boat Quality Assurance

Construction, reliability, durability and appearance are the most important elements when assuring a boat's quality. Particularly to ensure the whole boat is watertight and marine electronics are working sufficiently.

Boat Shipping

After the boat is built, it is wrapped up and ready to be shipped using boat transport. However, if a client chooses to drive the boat back directly, SSF will provide necessary assistance to make sure the boat arrive safely. ![]()

More about SSF – a boat builder with 43 years of experience

Previous: Deep Sea FRP Fishing Boat - -55°C, 50-300 (39m) Ton

Article sections

- SSF's Skillful Boat Building Technique & Being Trustworthy Earns Orders (NEW!)

- Solid, advanced fiberglass boat, luxury yacht

- Up to 340 Tons. Minus 60 Degrees Celsius Freezer Cooling System for Quality Sashimi

- 1,000 Fishing boats sold with DNV, CR, LR, BV certifications

- Shing Sheng Fa -- Work boat supply for gas & oil exploration, survey, pipeline repair

- Palau government buys passenger boat in Taiwan

- Catamaran | Passenger boat builder - SSF

- Deep Sea FRP Fishing Boat - -55°C, 50-300 (39m) Ton

- Fiberglass Boat Built With Advanced Technology - 100% One-Stop Fiberglass Boat Building

- Australian's amazing fiberglass boat experience in Taiwan

- 43-Year boat building experience

- Taiwan boat builder with 43 years of experience

- Send a boat inquiry

- Contact a Taiwan boat builder - SSF

- Shing Sheng Fa Boat Building Co., Ltd. privacy policy

Product category

Send an inquiry

Contact SHING SHENG FA BOAT BUILDING CO., LTD. Contact a boat builder for your boat building, yacht design, boat repair, and boat custom.

Ready e-Support

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Share

Search related products